Decision Tools - Coating Surfaces with Gold Nanoparticles

Coating surfaces with gold nanoparticles lends itself for use in applications as SERS, Lateral Flow, SPR detection, filters, and other surface chemistry applications.

We have a number of choices for coating surfaces with our nanoparticles. The nanoparticles include any of our Au, Ag, Pt, Pd, Cu, Ni, C, Fe3O4, or silica nanoparticles. Surfaces include glass, Au, Ag, Pt, Pd, Cu, Ni, Si, and others. We sell two different kits for the customer to bind to their own surfaces. Additionally we provide customized products that are completed to customer specifications.

Customer Kit #1: Quick and Easy Single Step Gold Nanoparticle Dropwise Kits on any surface

Applications: SPR, filters, surface chemistries. For use to create single particles and close pack surfaces

Nanopartz Gold Nanoparticles for Surfaces, are conjugated specifically for creating monodisperse surface coating of the complete line of Accurate Spherical Gold Nanoparticles and Gold Nanorods (or other shapes and materials upon request). This family of products is well known for creating both monodisperse, single particle, non agglomerated nanoparticles on surfaces, or with greater densities, close pack monolayers.

| Solvent | Dropwise addition | Quick Drying | Even Density Distribution | Particles dry unagglomerated (single particles) | Concentration Controlled By Dilution | Nanoparticles further functionalizable | Bond to glass surface | Separation between nanoparticle and surface (d) | |

| Citrate Capped | Water |

Yes | No | No | No | No | No | Ionic | 0.4nm |

| Nanopartz Surface Polymer | Proprietary | Yes | Yes | Yes | Yes | Yes | No | Ionic | 2nm |

| Nanopartz Covalent Surface Polymer | Proprietary | Yes | Yes | Yes | Yes | Yes | No | Covalent | 2nm |

Table 1. Kit #1 Characteristics

This is our easiest and most popular kit to use and is based on adding our prepared nanoparticles (2) in solution dropwise onto any surface. The most popular surfaces (1) are glass surfaces including slides and coverslips, as well as gold coated surfaces. We have three different options in this family of products.

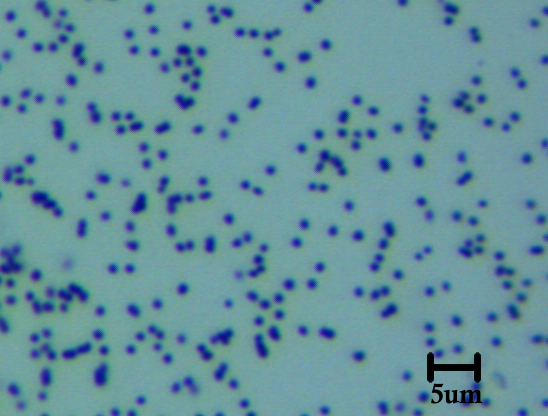

Figure 1. 40x Objective Dark Field of 1500nm Spherical Gold Nanoparticles on Glass Slide

The first option is a simple citrate stabilized gold nanoparticle. Adding dropwise to the slide surface results in a long drying time since the solvent is water. Additionally because the water dries in rings, the resultant nanoparticles on the surface result in an agglomeration of rings. Typically 10% of nanoparticles dry in an unagglomerated fashion (ie single particles). The result is an ionic attachment to the slide surface that if rehydrated, is removed from the surface. Consequently the nanoparticles are not considered further functionalizable. The citrate ligand length (2) is approximately 0.4nm, providing the spacing between the nanoparticle and the slide surface.

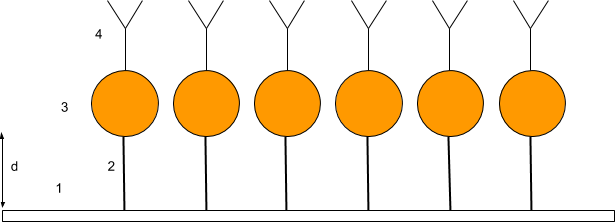

Figure 2. Block diagram of Kit #1. (1) Surface; (2) Spacer; (3) Nanoparticle

The second option utilizes a proprietary Nanopartz Organic Polymer functionalized nanoparticle in a proprietary alcohol. When added to the surface dropwise, this option results in a highly density controllable surface of nanoparticles with more than 80% of the nanoparticles guaranteed to be unagglomerated. Density of the nanoparticles on the surface is controllable through dilution and an even surface dispersion is guaranteed. The product dries in a few seconds and repeat applications can increase the surface density. This option results in nanoparticles that are approximately 1nm (2) from the surface. The ionic bond is not resistant to rehydration so this product is not considered further functionalizable.

The third option utilizes a proprietary Nanopartz Covalent Organic Polymer functionalized nanoparticles in a proprietary alcohol. Like option 2, when added to the surface dropwise, this option results in a highly density controllable surface of nanoparticles with more than 80% of the nanoparticles guaranteed to be unagglomerated. Density of the nanoparticles on the surface is controllable through dilution and an even surface dispersion is guaranteed. The product dries in a few seconds and repeat applications can increase the surface density. This option results in nanoparticles that are approximately 1nm (2) from the surface. This option is different from option 2 in that the result is a covalent (strong) bond to the surface. Repeated washings will not remove these nanoparticles.

Customer Kit #2: Gold Nanoparticle surface coating kits that may be further functionalizable

Applications: SERS, Filters, Surface Chemistries

This kit family comes with reagents and nanoparticles necessary for easy functionalization onto many surfaces using any of our nanoparticle products. Further, options for binding exact distances from surfaces, as well as the nanoparticles being further functionalizable.

In this kit we provide (1) Surface (optional, includes glass, Au, Ag, Pt, Pd, Cu, Ni, Si, and others); (2) A customizable length covalent bridge between the surface and the gold nanoparticle from 1nm to 100nm; (3) Nanoparticle, (spheres, rods, wires - Au, Ag, Pt, Pd, Cu, Ni, C, Fe3O4, or silica); (4) Further functionalizable ligand including active groups such as amine, carboxyl, biotin, streptavidin, antibodies, oligos, peptides, and more.

Figure 3. Block diagram of Kit #2 (1) Surface; (2) Spacer; (3) Nanoparticle; (4) Functionalization

This kit provides the Customer with control over; (1) surface type; (2) separation distance between the nanoparticle and the surface; (3) nanoparticle type and shape; and (4) resultant functionalization.

This kit varies with the number of steps depending on the options stated, but essentially is three to four steps. No special lab equipment is necessary and typical preparation times are one hour. A typical procedure is included in this Gold Nanoparticles on Surfaces Technical Note.

The procedure includes adding reagents dropwise resulting in a highly density controllable surface of nanoparticles with more than 80% of the nanoparticles guaranteed to be unagglomerated. Density of the nanoparticles on the surface is controllable through dilution and an even surface dispersion is guaranteed. The product dries in a few seconds and repeat applications can increase the surface density. Repeated washings will not remove these nanoparticles.